Safety is essential for protecting workers and ensuring the success of projects. From the consistent use of personal protective equipment (PPE) to following comprehensive safety protocols, every aspect plays a vital role in minimizing risks. It’s crucial to have clear procedures in place for emergencies, safe equipment handling, and safe work practices such as proper lifting, machine safety, and fall protection. Regular safety inspections, thorough training programs, and open communication among team members are key to maintaining a safe and productive work environment.

Personal Protective Equipment (PPE) Usage

Chemical Handling & Spill Response

Fire Safety and Extinguisher Use

Lockout/Tag Out Procedures

The Dirty Dozen

Emergency Procedures

Proper Lifting Procedures

Harness Safety

Apron & Hangar Procedures

Effective craftsmanship relies on mastering the use of hand tools. Choosing the right tool, maintaining it, and using it safely are key to achieving precision and efficiency. Through regular training on proper tool usage and maintenance, technicians ensure tools perform at their best. Inspections, skill development, and open communication contribute to a safe and productive work environment. By prioritizing the care and correct use of hand tools, technicians uphold high standards and foster creativity and innovation in their projects.

Tool Identification & Use

Precision Drilling

Cable Swaging

Fastener Installation

Difference Between ASE & Metric Tools & Hardware

Specialty Torque Tools

Fixed Base Operator (FBO) plays a vital role in private and charter aviation, offering services like refueling, marshalling aircraft, ground handling, maintenance, and catering to passengers. Students learn skills such as marshalling, ground service equipment operations, and safety procedures. FBOs also provide luxury services and manage tasks like flight planning and customs for international flights, ensuring efficient and comfortable air travel.

Ground Handling & Fuel Management

Customer Service & Management

Facility & Financial Management

Regulatory Compliance & Safety

FBO Operations & Services

Landing gear training equips individuals with the specialized skills needed for careers in aerospace and aviation. This comprehensive program covers the design, operation, and maintenance of landing gear systems, focusing on hydraulic systems, structural dynamics, and materials science. Students gain hands-on experience in inspecting, disassembling, overhauling, reassembling, and testing components, ensuring they meet strict safety and regulatory standards. By combining theoretical knowledge with practical application, graduates are prepared for roles in aircraft maintenance, aerospace manufacturing, and aviation management, highlighting the critical role of landing gear systems in flight safety and operational efficiency.

Components of Landing Gear Systems

Types of Landing Gear Actuator Configurations

Landing Gear Materials & Construction

Maintenance & Inspection Procedures

Troubleshooting Landing Gear Issues

Understanding Brake Fires, Causes, & Appropriate Response Procedures

Engine repair training prepares individuals for careers in aerospace by focusing on the maintenance, repair, and operation of aircraft engines and related systems. The program covers essential topics such as fuel systems, lubrication, and troubleshooting, with hands-on training in inspecting, repairing, and overhauling engine components and other aircraft parts. By blending theoretical knowledge with practical application, graduates are ready for roles in aircraft maintenance, overhaul facilities, and aviation engineering, contributing to the safety and efficiency of aircraft operations.

Engine Types & Components

Engine Operation & Performance

Maintenance & Troubleshooting

Repair Techniques & Overhaul

Regulatory Compliance & Safety

Soft skills training equips individuals with essential interpersonal and professional abilities for all career fields. These courses focus on effective communication, ethical decision-making, and maintaining a professional demeanor in diverse workplace settings. Participants also develop practical job-seeking skills, including resume building and interview techniques, while learning to navigate organizational hierarchies, manage conflicts, and uphold confidentiality. By emphasizing both theory and real-world application, graduates are well-prepared for roles in management, customer service, and administrative positions, highlighting the importance of soft skills in career advancement and workplace success.

Professionalism

Effective Communication

Ethical Decision Making

Time Management

Professional Development

Networking

Conflict Resolution

Resume Building

Drone technology training equips students with essential skills for careers in aerial imaging, surveying, and public safety. Furthermore, this specialized program focuses on UAV systems, emphasizing assembly, repairs, and programming, while prioritizing flight control, mission automation, and adherence to FAA regulations. Through an immersive approach, students learn to operate drones safely, troubleshoot mechanical and electrical issues, and effectively prepare for the Remote Pilot Certificate to meet industry standards. Ultimately, graduates are well-prepared for roles in agriculture, construction, and emergency response, where mastery of UAV operations proves indispensable for success.

Introduction to Electricity

Measurement of Circuits

525 Multimeter Use

This course equips individuals with essential skills for careers in aviation, automotive and manufacturing industries. It focuses on the precise application of torque using tools like torque wrenches and pneumatic drivers, while also covering safety wiring techniques to secure fasteners. Students will learn to calculate torque requirements, interpret assembly instructions, and apply safety wiring methods in real-world settings. Graduates are prepared for roles in automotive assembly, machinery maintenance, and construction, where precision and safety are critical.

Fabrication of Aircraft Panels

Rivet Installation & Removal

Damage Assessment & Repair

Bending & Forming Techniques

Seating Techniques

Aircraft Landing Gear Torque

Internal Component Torque

Safety Wire Methods

The sheet metal training program equips individuals with essential skills for careers in manufacturing, construction, and aerospace. Students learn to cut, bend, and shape metal sheets to precise specifications using various tools and machinery. The curriculum emphasizes both theoretical knowledge and hands-on practice, teaching students how to read blueprints, interpret technical diagrams, and fabricate components like aircraft parts. Adherence to industry standards and safety protocols is also emphasized, preparing graduates for roles in sheet metal fabrication, HVAC installation, and aircraft assembly.

Fabrication of Aircraft Parts

Rivet Installation & Removal

Damage Assessment & Repair

Bending & Forming Techniques

Seating Techniques

Multimeter training programs equip individuals with essential skills for careers in electronics repair, electrical engineering, and avionics. These comprehensive courses cover electrical circuits, accurate measurement of voltage, current, resistance, and troubleshooting techniques using various metering tools. Students apply Ohm’s Law, interpret schematic diagrams, and follow safety guidelines and industry standards. Emphasizing both theory and hands-on practice, graduates are prepared for diverse roles in electronics maintenance, renewable energy systems, and industrial automation, highlighting the vital role of multimeter training.

Circuit Continuity Testing

Voltage Measurement

Resistance Measurement

Diagnosing Electrical Faults

Measuring Amperage Draw

Proper documentation by technicians is critical for maintaining safety, compliance, and operational efficiency. Technicians must accurately record maintenance activities, inspections, and repairs, noting tools, materials, and methods used, as well as any deviations from standard procedures. This ensures traceability, compliance with regulations, and the ability to review for safety audits. Technicians are also responsible for signing off on tasks, confirming that all work meets safety and quality standards, and verifying that equipment is fit for use. Accurate documentation supports future maintenance and troubleshooting by providing a clear record of work performed.

Recognizing the “Dirty Dozen” Human Factors in Safety

Ethics in Maintenance Practices

Addressing Human Factors in Aviation

Reading & Interpreting Aircraft Manuals

Navigation of Table of Contents & Index

Understanding ATA Codes

Use of Illustrations and Diagrams in Manuals

Following Procedures for Proper Installation

Identifying & Avoiding Maintenance Errors

Ensuring Proper Torque Application

Importance of Timely Maintenance

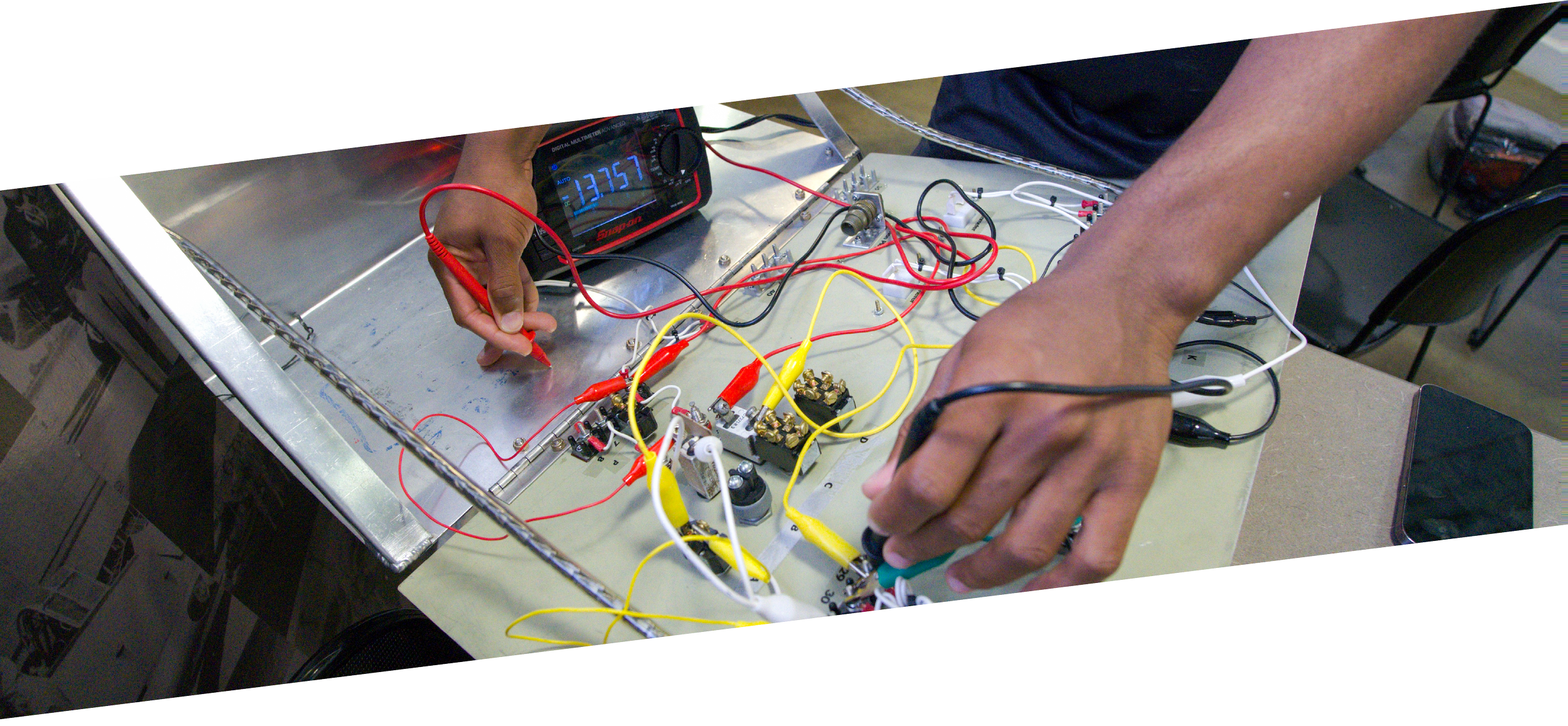

Avionics are the advanced electronic systems that ensure aircraft operate safely and efficiently. From navigation and communication to monitoring and flight control, avionics play a vital role in modern aviation. It’s essential to follow strict maintenance schedules, perform regular diagnostics, and ensure all software and hardware components are updated. Proper training for technicians, adherence to aviation standards, and rigorous testing are critical for minimizing risks and enhancing operational reliability. A commitment to quality and attention to detail in avionics ensures safety and optimal performance for every flight.

Introduction to Electricity

Measurement of Circuits

525F Multimeter Use

Electrical Safety Testing

Precision measuring training equips students with essential skills for careers in manufacturing, engineering, and quality control. The curriculum covers the use of tools like calipers, micrometers, and coordinate measuring machines, focusing on verifying tolerances and ensuring dimensional accuracy. Students learn to interpret engineering drawings, apply Geometric Dimensioning & Tolerancing (GD&T) principles, and uphold quality standards. This hands-on training prepares graduates for roles in metrology labs, CNC machining, and quality inspection, where precision is key to success.

Caliper & Micrometer Use

Gauge Block Use

Dial Indicator Applications

Surface Plate Measurements

Blueprint Reading & Measurement

Difference Between ASE & Metric

Measurement SystemsFeeler Gauge Use